Boost the full potential of your chemical business with DoFort's advanced Chemical ERP Software in india. Designed for the specialty chemical industry, our solution streamlines everything from product development and production to inventory, quality control, and GHS regulatory compliance.

Whether you're a private-label manufacturer, co-packer, or operate at full scale, our software ensures seamless integration of manufacturing, sales, finance, and reporting. With extensive experience in solvents, polymers, paints, and more, we provide powerful features like lot traceability, formula management, and intelligent Bill of Materials calculations. Don't let complex regulations and fragmented systems hold you back; DoFort unified Chemical Manufacturing ERP Software helps you reduce costs, increase efficiency, and gain a competitive edge by automating compliance and optimizing every process from order entry to invoicing.

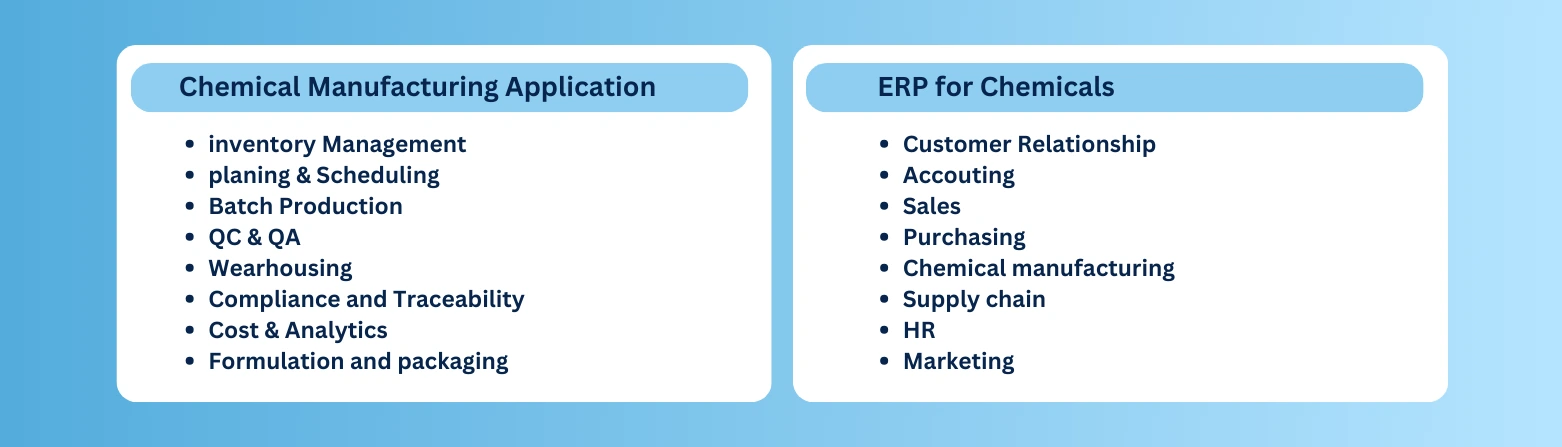

Chemical ERP software in india is a comprehensive solution that simplifies complex chemical manufacturing operations, including formula management, regulatory compliance, vendor collaboration, production planning, and batch processing. Designed to be flexible, customizable, and user-friendly, ERP for the chemical industry transforms traditional processes and empowers businesses to adapt to modern challenges with ease.

DoFort Chemical ERP software in india is a ready-to-deploy solution built for today’s competitive chemical landscape. It delivers end-to-end visibility and cutting-edge technology to help businesses excel. With advanced formula management, real-time inventory and warehouse control, compliance management, business intelligence tools, and integrated project management, best ERP for the chemical industry ensures greater efficiency, accuracy, and growth.

Unlock real-time insights and advanced technology with DoFort ERP to redefine your business. Harness powerful modules, intelligent automation, and analytics to streamline operations, reduce risks, and drive sustainable growth.

Optimize your chemical business with DoFort Chemical ERP Software in India. Our solution provides powerful formula management, allowing you to handle complex formulations, track reactions, and ensure product quality. Gain flexibility and security with our advanced ERP for chemical manufacturing, designed to streamline R&D and improve data integrity for a competitive edge.

Ensure regulatory compliance and safety with DoFort Chemical ERP Software in India. Our solution offers integrated SDS authoring and enhanced traceability to streamline the management of hazardous materials. This ERP for chemical manufacturing helps you meet GHS and Indian standards, ensuring precise labeling and audit readiness.

Gain total control and compliance with DoFort's Chemical ERP Software in india Our solution offers precise lot traceability and integrated MRP to streamline production. With robust recall procedures, this ERP for chemical manufacturing minimizes risk and ensures full regulatory adherence, keeping your business efficient and competitive.

Drive innovation with DoFort's Chemical ERP Software. Our solution empowers R&D to safely test new concepts and materials. Seamlessly transition new formulations to production, ensuring your business stays competitive. This is the ultimate ERP for chemical manufacturing in India.

Guarantee quality and compliance with DoFort's Chemical ERP Software in india. Our solution securely stores test data and provides audit trails, ensuring every product meets specifications. This ERP for chemical manufacturing helps you maintain strict quality control and regulatory adherence effortlessly.

Get real-time insights and a competitive edge with DoFort's Chemical ERP Software in india. Our advanced analytics and reporting tools track KPIs and ensure compliance, helping you optimize processes. This powerful ERP for chemical manufacturing gives you the data needed to make smarter, strategic decisions.

Chemical manufacturing ERP software enhances operational efficiency through functionalities such as real-time inventory oversight, traceability, material requirements planning (MRP) for improved production processes, and integrated safety data sheet (SDS) management. DoFort Chemical Software aids in maintaining regulatory compliance, increases productivity, and facilitates research and development for new product innovation, enabling companies in India to remain competitive in the market.

Welcome to DoFort !